+86-18017278995

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-13 Origin: Site

When you heat plastic, it doesn't melt the way metal does. Instead, it softens and flows over a range of temperatures. This is crucial for understanding how plastics perform in different applications. In this article, we'll explore what temperature plastic melts at, why it varies, and how to choose the right material for your needs.

The 'melting point' of a plastic refers to the temperature range at which it transitions from a rigid, solid state to a flexible, flowable liquid. This transition allows the material to be shaped, molded, or extruded into the desired form. However, because plastics can be either crystalline or amorphous, the exact behavior of melting varies.

The behavior of plastic when heated can differ greatly depending on its type. Plastics are broadly categorized into two groups:

Thermoplastics: These plastics soften when heated and can be reshaped multiple times. Common examples include polyethylene, polypropylene, and polycarbonate.

Thermosets: These plastics, once heated and molded, undergo a chemical change that prevents them from melting again. Examples include epoxy and phenolic.

Knowing the type of plastic you’re working with helps determine its melting point and suitability for your application.

Let's dive into the melting points of some of the most common plastics.

| Plastic Type | Melting Point (°C) |

|---|---|

| Polyethylene (PE) | 105 - 137 |

| Polypropylene (PP) | 160 - 175 |

| Acrylonitrile Butadiene Styrene (ABS) | 170 - 190 |

| Polyamide (Nylon) | 215 - 221 |

| Polycarbonate (PC) | 225 - 250 |

| Polyvinyl Chloride (PVC) | 210 |

The melting point of plastics is influenced by several factors, including:

Crystallinity: Crystalline plastics have a defined melting point, while amorphous ones soften over a range.

Molecular Structure: The arrangement of molecules within the polymer affects how easily it melts. Highly branched polymers tend to melt at lower temperatures.

Additives: Plastic blends with fillers, stabilizers, or plasticizers can lower or raise the melting point.

When plastic is heated, its molecules begin to gain energy, allowing them to move more freely. This transition from a solid to a molten state is essential for plastic processing techniques such as injection molding or extrusion. Depending on the type of plastic and the process, the melting point will affect how it behaves during production.

In manufacturing processes, such as injection molding, precise control of the plastic melting point is critical. If the material isn't heated to the correct temperature range, it may not fill the mold properly, leading to defects in the final product. Similarly, using a plastic beyond its melting point can degrade its structural integrity, making it unsuitable for use.

Tip: For consistent production, always verify the optimal processing temperature range of the plastic material you're using to avoid defects during molding.

Different plastics melt at different temperatures, and this property dictates their use in various industries. For example:

High-temperature applications: Plastics like PEEK (Polyether Ether Ketone) with melting points above 300°C are suitable for aerospace and automotive parts.

Consumer goods: Lower melting-point plastics, such as polyethylene (PE) and polypropylene (PP), are often used in packaging materials like bags, containers, and bottles.

Some plastics are specifically engineered to withstand high temperatures. Materials like polycarbonate (PC) and polyamide (Nylon) have relatively high melting points, making them ideal for applications where heat resistance is necessary.

Tip: If you're designing products for high-temperature environments, consider selecting thermoplastics like polycarbonate or nylon.

Plastics can be either crystalline or amorphous. Crystalline plastics have a well-ordered molecular structure, leading to a sharp melting point. Amorphous plastics, like ABS and polycarbonate, don't have a clear melting point and instead soften over a range of temperatures.

Crystalline plastics: Typically have a narrower melting point range.

Amorphous plastics: Do not melt at a single point but soften gradually as the temperature increases.

In practical terms, crystalline plastics are generally more heat-resistant and can maintain structural integrity at higher temperatures. Amorphous plastics, on the other hand, may exhibit better clarity and flexibility but may not perform as well in high-heat applications.

Tip: For applications requiring transparency and moderate heat resistance, consider amorphous plastics like acrylic.

Knowing the melting temperature of plastics is critical in determining the right processing method. For example:

Injection Molding: The plastic must be heated above its melting point to be injected into molds, where it cools and solidifies into shape.

Extrusion: This process involves pushing molten plastic through a mold to create long shapes, like pipes or sheets.

Blow Molding: Plastics with lower melting points are often used for making hollow objects like bottles.

Each manufacturing method requires different temperature ranges for the material. Here's a basic guideline:

Injection Molding: Typically requires temperatures slightly above the plastic's melting point for optimal flow.

Extrusion: Higher temperatures are needed to ensure the plastic flows smoothly through the die.

Blow Molding: Requires precise control to ensure the plastic maintains the right balance between stiffness and flexibility.

Tip: When choosing a plastic for manufacturing, always consult the material's datasheet for the recommended temperature ranges for specific processing techniques.

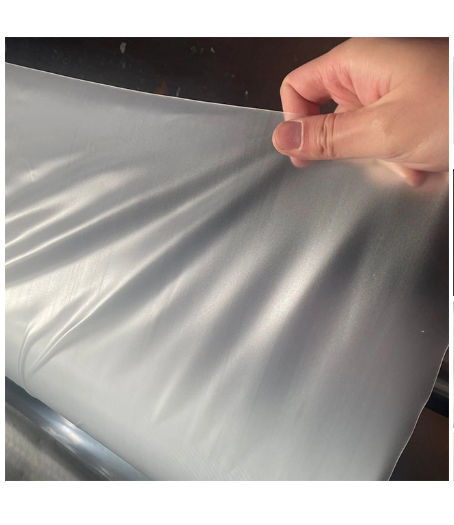

Understanding the melting point temperature of plastics is crucial for choosing the right material for your project. Whether you're designing for high-heat applications or focusing on flexibility, it's essential to know how plastics respond to heat. By considering factors like the type of plastic and its crystalline structure, you can make the best material choice for optimal performance. Huiyuan film offers products that help you select the ideal materials for your needs, providing unmatched value in terms of durability and performance.

A: The plastic melting point temperature varies by type. For example, polyethylene melts around 120-180°C, while PVC melts at 75-105°C.

A: Plastic has a melting point because its polymer chains break down when heated, causing it to soften and eventually melt at a specific temperature.

A: Factors like the polymer type, molecular weight, and crystalline structure affect the plastic melting point temperature.